Products

Big discounting Dd Motor - Stepping Motor and Ball / Leading Screw External Combination Linear Actuator and Through Shaft Screw Stepper Motor Linear Actuator – KGG Detail:

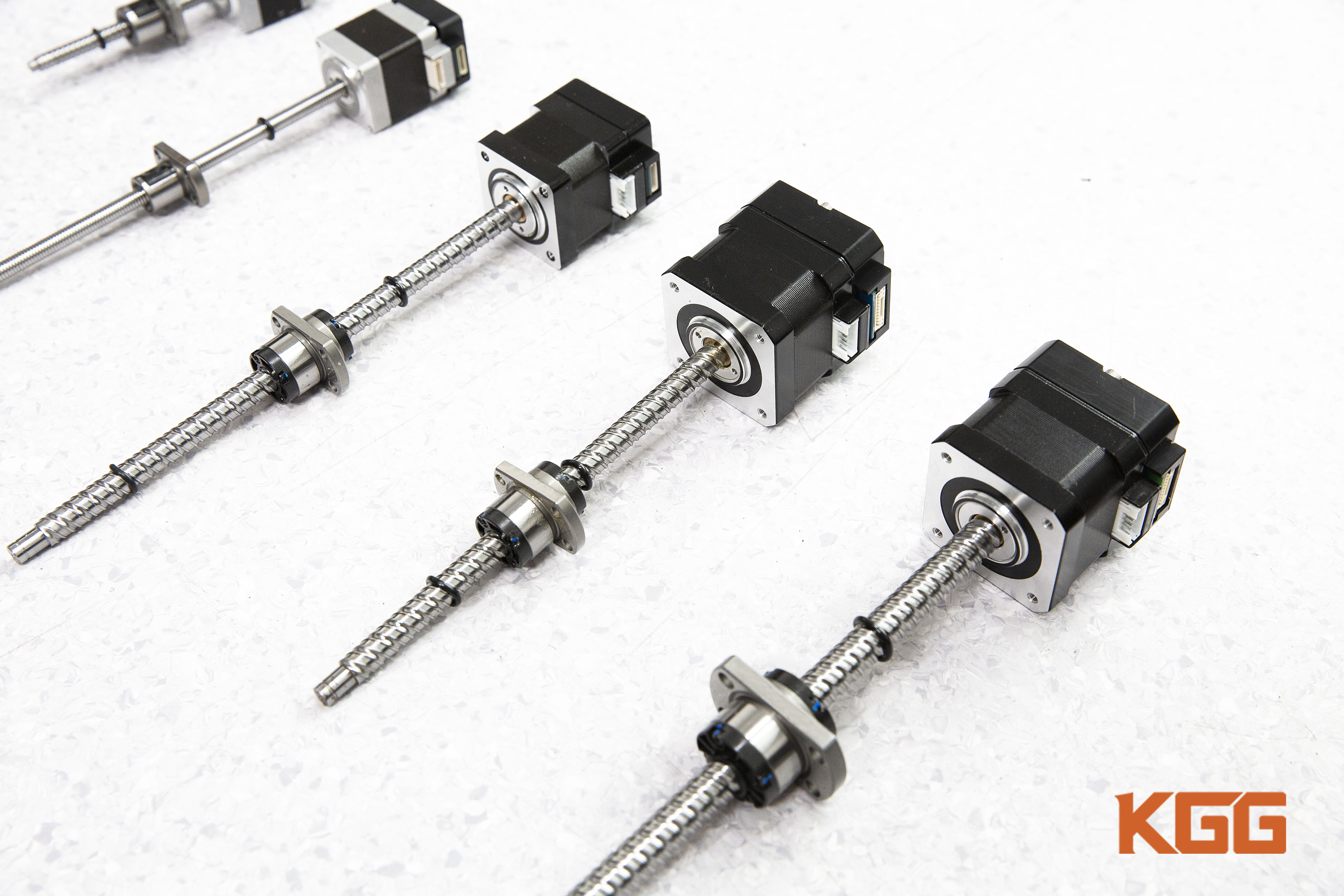

GSSD Ball Screw / Leading Screw External Linear Actuator

Structure upgrade, simple transmission: the 2-phase stepping motor is directly installed on the shaft end of the ball screw, and the ball screw shaft center is used as the ideal structure for the motor rotation axis.

Compact and lightweight: the 2-phase stepping motor and rolling ball screw are integrated products. Through the integration of the motor shaft and the ball screw shaft, no coupling is required, and the size of the long side is saved.

High precision, high stability, cost-effective: the combination of the rolling ball screw and the 2-phase stepping motor saves the coupling, and the integrated structure reduces the combined accuracy error, which can make the repeated positioning accuracy ±0.001mm.

Shaft ends are available in a variety of styles and can be customized as required. The motor specifications are 20, 28, 35, 42, 57 stepper motors, which can be matched with ball screws and resin sliding screws.

SLH Non-captive Shaft Screw Stepper Motor Linear Actuators

These linear actuators are ideal for applications that require a combination of precise positioning, rapid motion and long life. Typical applications include X-Y tables, medical equipment, semiconductor handling, telecommunications equipment, valve control, and numerous other uses. Various customizations are available upon request, such as screw lengths, custom designed nuts, anti-backlash nuts, safety brakes, encoders, etc.

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Big discounting Dd Motor - Stepping Motor and Ball / Leading Screw External Combination Linear Actuator and Through Shaft Screw Stepper Motor Linear Actuator – KGG , The product will supply to all over the world, such as: Turkmenistan, Rio de Janeiro, Serbia, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

You will hear from us quickly

Please send us your message. We will get back to you within one working day.

All fields marked with * are mandatory.

-

Top

.130.jpg)