Products

Factory wholesale Single Axis Stage - Planetary & Circulating Roller Column Screw – KGG Detail:

Roller Column Screw VS Roller Ball Screw

The bearing capacity of the rolling screw mainly depends on the radius of curvature of the contact surface between the rolling elements, the number of contact points, and the hardness and finish of the contact surface.

Under the conditions of the same hardness, smoothness and precision of the contact surface, the roller screw has more contact points than the ball screw, and the radius of curvature of the enveloping circle of the roller contact surface is also much larger than that of the ball screw. This determines that the roller screw has a higher load capacity than the ordinary ball screw.

Classification And Application Of Roller Screws

Roller screw can be divided into planetary roller screw and circulating roller screw according to different structures. There are essential differences between the two in the operation mode of the rollers: the rollers of the planetary roller screw do not move axially relative to the nut during revolution and rotation, while the recirculating roller screw does not only perform revolution and rotation. In addition, relative to the nut, there is a cyclic movement of the nut.

Planetary Roller Screw

Circulating Roller Screw

The difference in structure determines that the two have different application fields. The planetary roller screw pair is mainly used in the dry and heavy load field, while the circulating roller screw is biased towards precision equipment. Planetary roller screws have high bearing capacity and high reliability, and are mainly used in:

● Press machine tools ● Injection molding ● Military equipment ● Iron and steel industry ● nuclear industry

Circulating roller screws with high lead resolution, coupled with its high load carrying capacity and high reliability, it is mainly used in:

● Precision instruments ● Precision grinders ● Aerospace ● Medical equipment

Roller Column Screw

GZR Planetary Roller Column Screw

Planetary Roller Screws with centrally located nut flange and no axial preload.

GZV Circulating Roller Column Screw

Circulating Roller Screws with centrally located nut flange and no axial preload.

CHR Planetary Circulating Roller Column Screw

Highest efficiency rolling motion (even in shallow lead designs).

Multiple contact points that carry large loads with very high resolution.

Small axial movement (even with very shallow leads).

CHRC Planetary Circulating Roller Column Screw

High rotational speeds with faster acceleration (no adverse effects).

The most reliable screw solution available.

Higher cost option with highest performance.

CHRF/CHRP Planetary Circulating Roller Column Screw

Maximum backlash of single nuts: 0.03mm (can be less on request).

Nuts with lubrication holes available if required.

CHRI Inverted Planetary Roller Screws

An inverted roller screw works on same principle as a planetary roller screw. In order to reduce the overall actuator dimensions, either the nut or screw can be directly used as a push tube.

An inverted roller screw has a high speed capability similar to a planetary roller screw, but the load acts directly on the translating push tube.

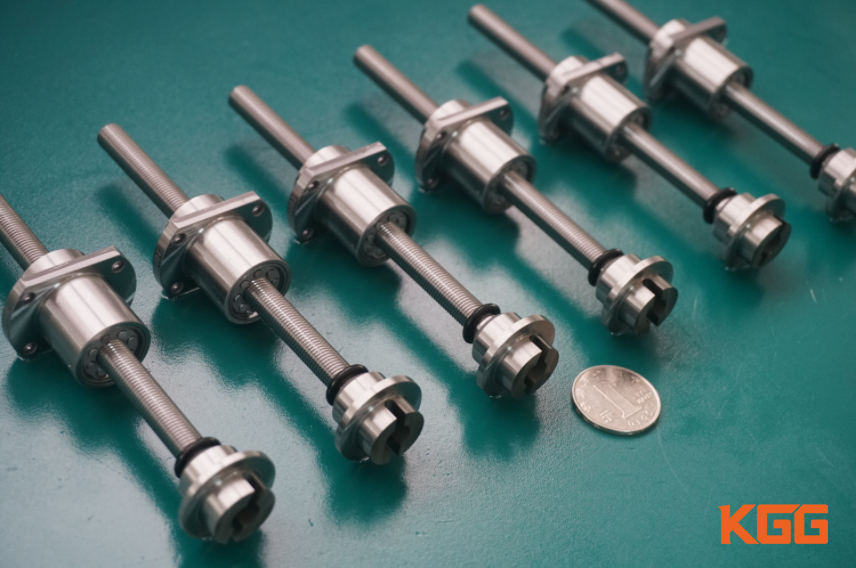

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for Factory wholesale Single Axis Stage - Planetary & Circulating Roller Column Screw – KGG , The product will supply to all over the world, such as: Barbados, Netherlands, Switzerland, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

You will hear from us quickly

Please send us your message. We will get back to you within one working day.

All fields marked with * are mandatory.

-

Top